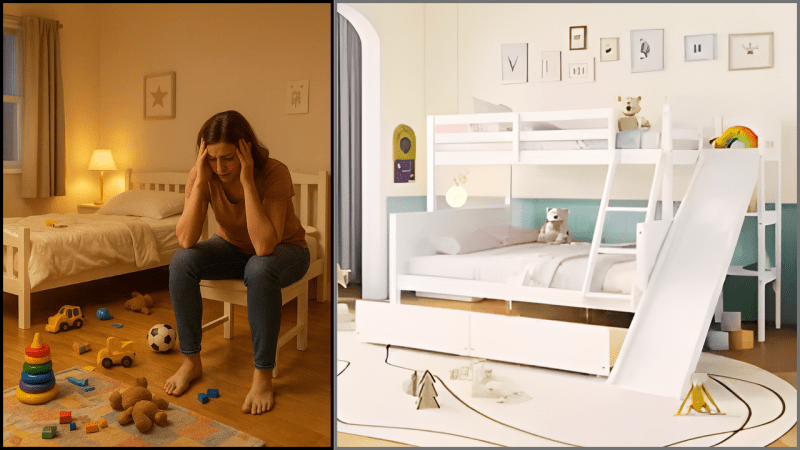

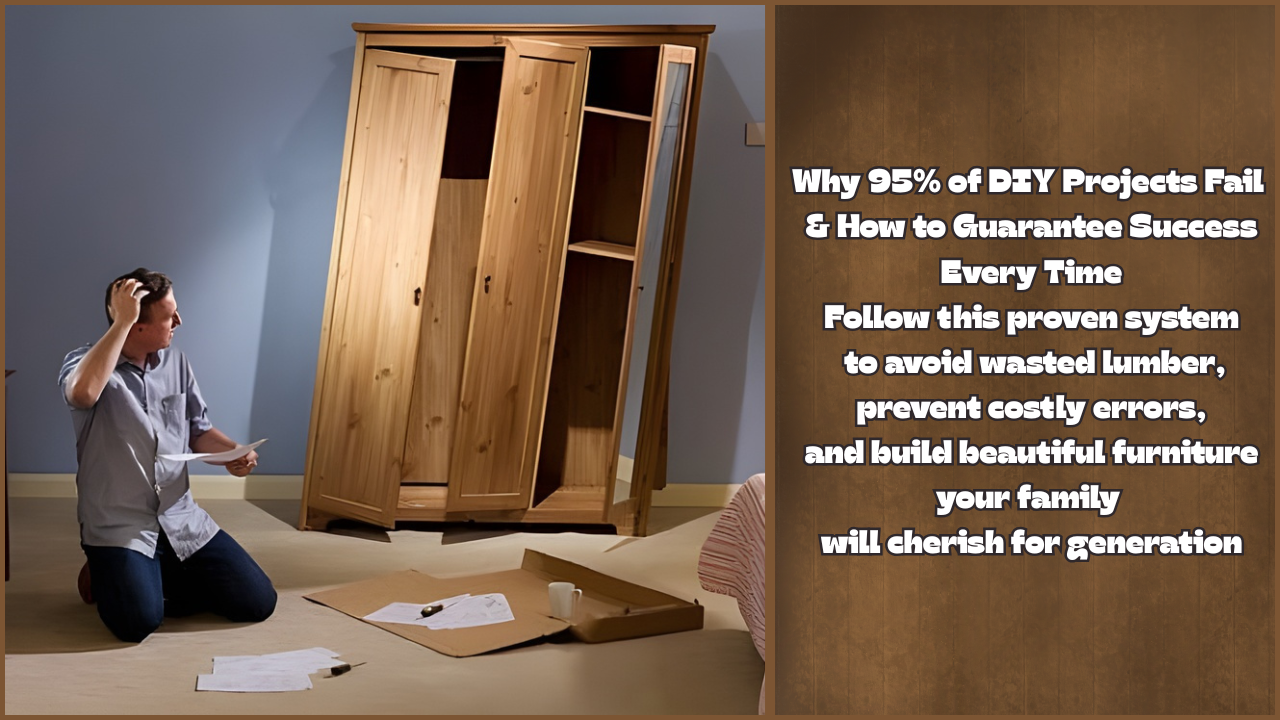

Why Most DIY Woodworkers Waste Thousands on Failed Projects

You've got the passion. You've got the tools. You've got the garage or basement workshop. But somewhere between Pinterest inspiration and finished product, something goes wrong.

Maybe the cuts were off. Maybe the wood warped. Perhaps the joints didn't fit. Or maybe you just gave up halfway through because the instructions were confusing and you didn't know what to do next.

The truth? These failures aren't because you lack skill or talent. They happen because you're making one (or more) of seven critical mistakes that almost every DIY woodworker makes—especially when starting out or returning to the hobby after years away.

The good news: These mistakes are 100% preventable. Once you know what they are and how to avoid them, you'll build projects that actually turn out the way you envisioned—on time, on budget, and with minimal waste.

The 7 Deadly Mistakes Explained

Starting Without a Detailed Plan

Why this fails: Your brain remembers what the finished project looks like, but it doesn't remember the exact dimensions, the wood thickness, the joint types, or how all the pieces fit together. You end up making decisions on the fly, which leads to:

- Buying the wrong amount of wood (too much or too little)

- Cutting pieces that don't fit together

- Discovering halfway through that you're missing a critical step

- Wasting hours trying to figure out what to do next

- Before buying any materials, write down every single dimension for your project

- Create a complete materials list with wood species, thickness, width, and length

- Draw or find diagrams showing how each piece connects to the others

- Number each step in the building process in order

- Review your plan one final time before purchasing materials

Buying the Wrong Wood or Wrong Amount

Why this fails: Different woods have different properties. Some warp easily. Some are too soft. Some are too expensive. And buying the wrong amount means either:

- You run out mid-project and have to buy more (at a premium price)

- You have leftover wood that you paid for but didn't use

- The wood you bought doesn't work with your project design

- List every single piece of wood needed for your project with exact dimensions

- Specify the wood species and grade (construction grade, select, etc.)

- Calculate total board feet needed

- Add 10% to your total for waste and mistakes

- Bring your written list to the lumber yard and stick to it

Skipping the Prep Work and Setup

Why this fails: Prep work takes time, but it saves exponentially more time later. Without proper setup:

- Your cuts are inaccurate, causing pieces not to fit together

- Your wood is warped or twisted, ruining the final product

- You make the same mistake repeatedly because your tools aren't set up right

- You waste materials because you have to redo cuts

- Flatten and joint all your wood before cutting

- Set up your primary tools (table saw, miter saw, etc.) with test cuts

- Create a jig or guide for any repetitive cuts

- Measure twice, cut once—verify every measurement before cutting

- Do a dry assembly to make sure all pieces fit before finishing

Using the Wrong Joinery Method

Why this fails: Different joints have different strengths. Using the wrong joint means:

- Your project falls apart after a few months

- Joints fail under stress or weight

- Your furniture looks cheap and unstable

- You have to rebuild the entire project

- Identify which joints your project requires

- Practice the joint on scrap wood before using it on your project

- Follow your plan's instructions exactly for joint layout and creation

- Test the joint strength before final assembly

- Use appropriate fasteners (screws, dowels, etc.) for your joint type

Not Accounting for Wood Movement

Why this fails: Wood is a living material. It moves. If you don't design your project to accommodate this movement:

- Joints split and crack

- Panels warp and twist

- Doors and drawers become difficult to operate

- Your beautiful project becomes unusable

- Understand how wood moves in your climate (high humidity vs. dry)

- Use frame-and-panel construction for large panels

- Allow 1/8" to 1/4" clearance for wood movement in slots and grooves

- Use elongated holes for fasteners on wide boards

- Avoid gluing wood edges that need to move

Rushing Through Finishing

Why this fails: Finishing is 50% of what makes a project look professional. Rushing it means:

- Rough, uneven surface that feels cheap

- Finish drips, runs, or pools in corners

- Finish peels or flakes off after a few months

- Your beautiful woodwork looks amateur

- Sand progressively: 80 grit → 120 grit → 150 grit → 220 grit

- Fill any gaps or holes with wood filler before final sanding

- Apply thin coats of finish (stain, polyurethane, etc.) rather than thick ones

- Sand lightly between coats with 220-grit paper

- Allow full drying time between coats (follow manufacturer instructions)

- Apply final coat and let cure fully before use

Not Learning From Your Mistakes

Why this fails: Without reflection and learning, you never improve. You'll:

- Repeat the same mistakes on every project

- Never develop the skills to build more complex projects

- Continue wasting materials and money

- Become frustrated and give up on woodworking

- After completing a project, take photos of the finished piece

- Write down 3 things that went well

- Write down 3 things that didn't go as planned

- For each problem, write down the root cause

- Write down how you'll avoid that problem on your next project

- Review your notes before starting your next project

What Happens When You Avoid These Mistakes

What Woodworkers Are Saying

Ready to Build Projects That Actually Turn Out?

Imagine having access to thousands of detailed woodworking plans—each one with exact measurements, complete materials lists, step-by-step instructions, and professional diagrams.

Imagine never having to search for plans again. Never wonder if your plan is accurate. Never guessing about measurements or materials. Just clear, detailed instructions that guide you from start to finish.

That's exactly what you get with TedsWoodworking: 16,000 Woodworking Plans & Projects.

Every plan includes everything you need to avoid the 7 deadly mistakes you just learned about:

- ✓ Exact cutting lists and materials specifications

- ✓ Detailed step-by-step instructions

- ✓ Professional diagrams and schematics

- ✓ Proper joinery techniques explained

- ✓ Finishing instructions for professional results

Get Access to 16,000 Plans Now

Join thousands of DIY woodworkers who are building beautiful projects with confidence. Your next masterpiece is waiting.